In technical drawing, accurate representations of objects is

very important for effective communication between designers, engineers, and

manufacturers. One basic aspect of this process is to create the orthographic

views, which provide details of an object's dimensions, shapes, and features

from various perspectives.

Orthographic Views

Orthographic views, also known as multi-view projections,

depict an object using two or more flat 2D images, each showing a different

side or perspective. These views are essential for conveying a comprehensive

understanding of an object's form and structure.

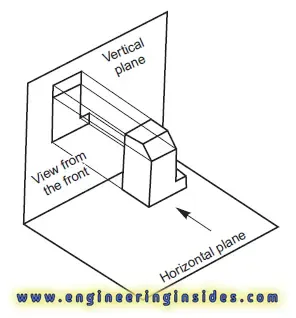

View from the Front

The view from the front of an object is obtained by

projecting it onto a vertical plane while looking directly at its front

surface. This perspective is crucial for capturing the primary features and

details of the object.

View from Above

The view from above illustrates the object's projection onto

a horizontal plane, observed by looking down on its top surface. This

perspective provides valuable information about the object's layout and spatial

arrangement.

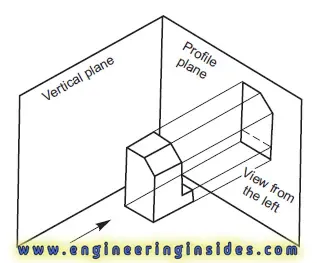

View from the Side

The view from the side involves projecting the object onto a profile plane while looking perpendicular to its side surface. Since objects have two distinct sides, left and right, two separate views – one from the left and one from the right – can be obtained to depict the object comprehensively.

Importance of Orthographic Views

Clarity and Precision: Orthographic views ensure that every

aspect of the object is represented accurately, facilitating clear

communication among stakeholders.

Dimensional Analysis: Engineers and designers rely on

orthographic views for precise measurements and dimensional analysis, aiding in

the manufacturing and assembly processes.

Error Reduction: By providing multiple perspectives,

orthographic views help identify potential design flaws or discrepancies early

in the development phase, minimizing errors and costly revisions later on.

Methods for Obtaining Orthographic Views

Front View:

Position the object such that its front surface is directly

facing the observer.

Project the object onto a vertical plane perpendicular to

the observer's line of sight.

Capture all significant features and details visible from

the front perspective.

Top View:

Place the object on a horizontal plane.

Observe the object from directly above, looking down onto

its top surface.

Project the object onto the horizontal plane to create the

top view, highlighting its layout and spatial arrangement.

Side View:

Choose the desired side of the object (left or right).

Position the object such that the chosen side surface is

perpendicular to the observer's line of sight.

Project the object onto a profile plane to obtain the side

view, capturing the features specific to that side.

Practical Applications of Orthographic Views

Engineering and Design: Orthographic views are widely used

in engineering and design to create technical drawings, schemes, and blueprints

for various projects like architectural structures and mechanical components.

Manufacturing and Fabrication: Manufacturers rely on

orthographic views to understand the precise dimensions and specifications of

the products they are tasked with producing, ensuring accuracy during

fabrication processes.

Education and Training: Students studying technical subjects

like engineering, architecture, and industrial design learn to translate and

create orthographic views as part of their curriculum which develops effective

skills for their future careers.

Orthographic views play a crucial role in technical drawing,

providing detailed and accurate representations of objects from multiple

perspectives. By mastering the methods for obtaining these views and

understanding their significance, designers, engineers, and manufacturers can

enhance communication, reduce errors, and streamline the design and production

processes.

Frequently Asked Questions

1. What are orthographic views, and why are they essential

in technical drawing?

Orthographic views, also known as multi-view projections,

are 2D representations of objects from different perspectives, such as front,

top, and side views. They are vital in technical drawing because they provide

comprehensive insights into an object's dimensions, shapes, and features,

facilitating clear communication and accurate depiction for design,

engineering, and manufacturing purposes.

2. How is the view from the front of an object obtained, and

what information does it convey?

The view from the front of an object is obtained by

projecting it onto a vertical plane while looking directly at its front

surface. This perspective reveals most of the important features of the object,

including its shape, contours, and significant details, aiding in visualizing

its overall appearance and structure.

3. Describe the process of obtaining the view from above of

an object.

The view from above of an object is acquired by projecting

it onto a horizontal plane while observing it from directly above, looking down

on its top surface. This perspective provides valuable information about the

object's layout, spatial arrangement, and relationships between different

components or elements.

4. Why are there typically two possible views from the side

of an object, and how are they obtained?

Objects have two distinct sides, left and right, leading to

two possible views from the side: view from the left and view from the right.

These views are obtained by projecting the object onto a profile plane while

looking perpendicular to its respective side surface, allowing for a

comprehensive depiction of the object's features from both perspectives.

5. What are some practical applications of orthographic

views in various industries?

Orthographic views find widespread applications in

engineering, design, and manufacturing industries. They are used to create

technical drawings, blueprints, and schematics for architectural structures,

mechanical components, and other products. Manufacturers rely on orthographic

views to ensure accuracy during fabrication processes, while students in

technical fields learn to interpret and create these views as part of their

education and training.

6. How do accurate orthographic views contribute to error

reduction in the design and manufacturing processes?

Accurate orthographic views help identify potential design

flaws or discrepancies early in the development phase, minimizing errors and

costly revisions during the manufacturing process. By providing multiple

perspectives and precise measurements, orthographic views enable engineers and

designers to detect and address issues before they escalate, ensuring the final

product meets quality standards and specifications.